Unlocking the Potential of Flexible Manufacturing Systems

Introduction: The business and industrial landscapes are continuously evolving, driven by technological advancements and market dynamics. One such development that has been quietly revolutionizing the manufacturing sector is the adoption of Flexible Manufacturing Systems (FMS). This article delves into the intricacies of FMS, shedding light on its background, current trends, and potential impacts on the business landscape.

A Historical Overview of Flexible Manufacturing Systems

Tracing its roots back to the 1960s, the concept of FMS was developed as a response to the limitations of traditional manufacturing systems. These older systems were characterized by inflexibility, high costs, and inefficiency, especially when handling complex or varying product designs. FMS emerged as a viable solution, allowing manufacturers to adapt quickly to changing market demands without incurring significant costs or disruptions. Over the years, advancements in technology have further enhanced the capabilities and efficiency of FMS, making it an attractive option for modern businesses.

Current Trends and Insights

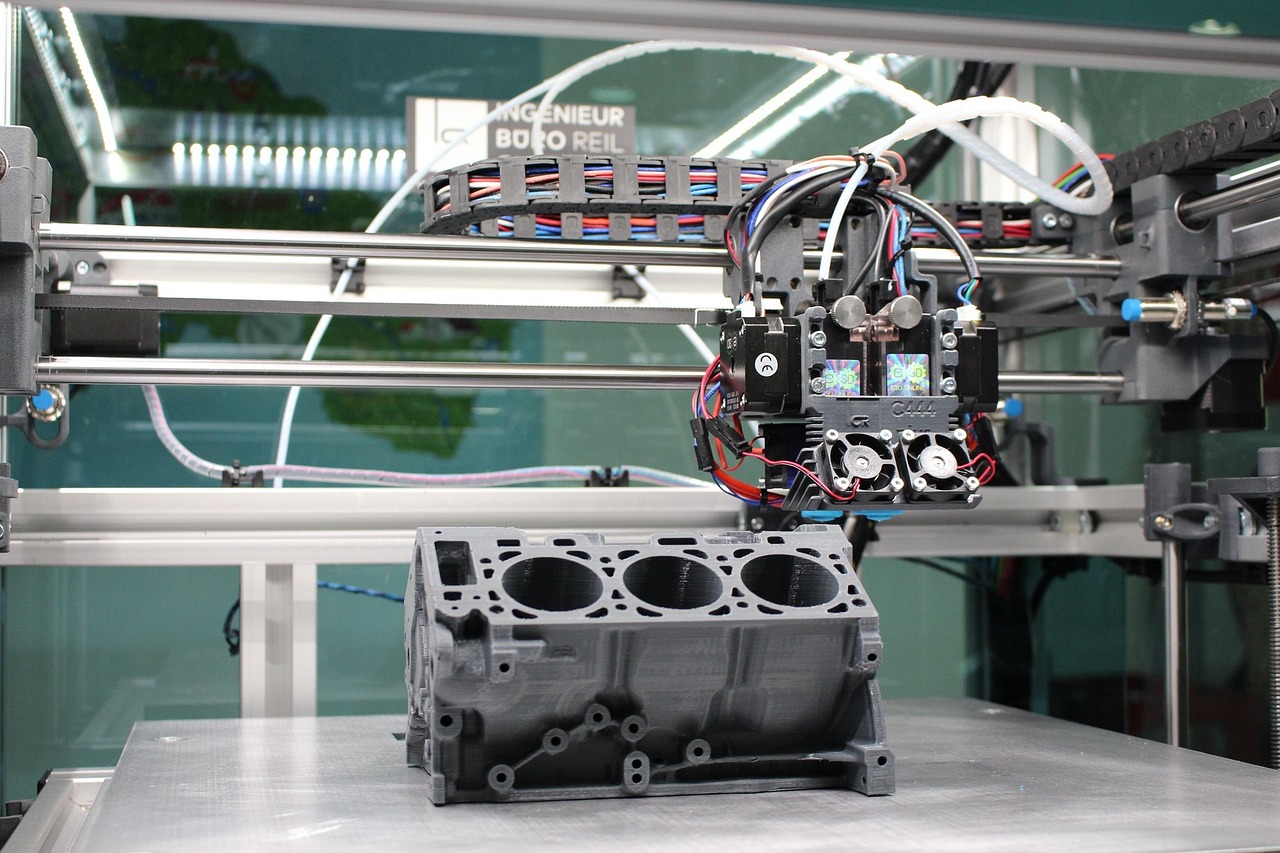

Today, FMS is at the forefront of manufacturing innovation, with numerous businesses adopting this system to enhance their operational efficiency and competitiveness. The advent of technologies such as robotics, automation, and data analytics has maximized the potential of FMS, allowing businesses to achieve unprecedented levels of productivity and flexibility. Furthermore, the ongoing COVID-19 pandemic has underscored the importance of adaptability and resilience in business operations, further driving the adoption of FMS.

The Impact of Flexible Manufacturing Systems

The benefits of adopting FMS are manifold. Key among them is the ability to rapidly adapt to changes in product demand or design, thereby minimizing downtime and waste. FMS can also enhance productivity, as it allows for seamless switching between different product lines without requiring significant setup time. However, implementing FMS also presents certain challenges, such as the need for sizable initial investment and a well-trained workforce.

Practical Insights into FMS Adoption

- Start small: Begin with a small-scale FMS before scaling up to a full-fledged system. This allows for a smoother transition and helps identify potential issues early on.

- Invest in employee training: A successful FMS implementation requires a workforce skilled in operating and maintaining the system.

- Leverage technology: Modern technologies, such as robotics and data analytics, can greatly enhance the efficiency and capabilities of FMS.

- Plan for the long term: FMS is a strategic investment that yields significant benefits over time. Hence, businesses should factor in long-term goals and market trends when planning for FMS adoption.

Closing Thoughts:

Flexible Manufacturing Systems offer a promising solution to the challenges of modern manufacturing, providing businesses with the agility and efficiency needed to thrive in today’s dynamic market environment. While the adoption of FMS requires investment and planning, the potential benefits make it a worthwhile endeavor. By gaining a deeper understanding of FMS and strategically implementing it, businesses can unlock new levels of productivity and competitiveness.